In the fiercely competitive food, beverage, and daily chemical industries, every unplanned production line shutdown translates to significant losses. Are you still enduring frequent replacements, product scratches, lubricant contamination, and annoying noise from your pusher wheel components? This is no longer an unavoidable “operating cost” but a critical area demanding technological advancement.

I. Transcending Tradition: Redefining Performance Standards for Production Line Paddles

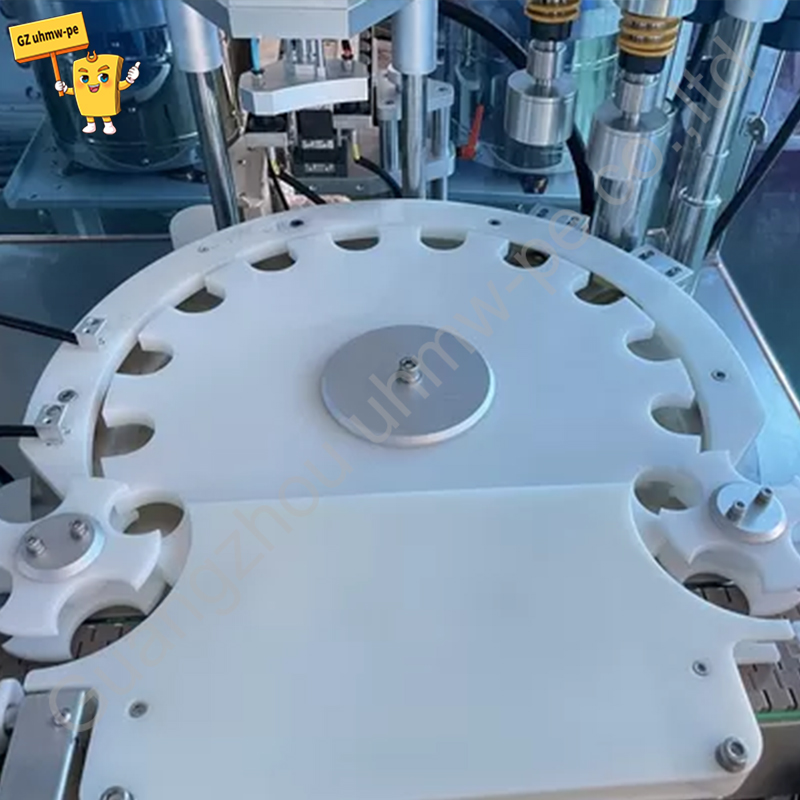

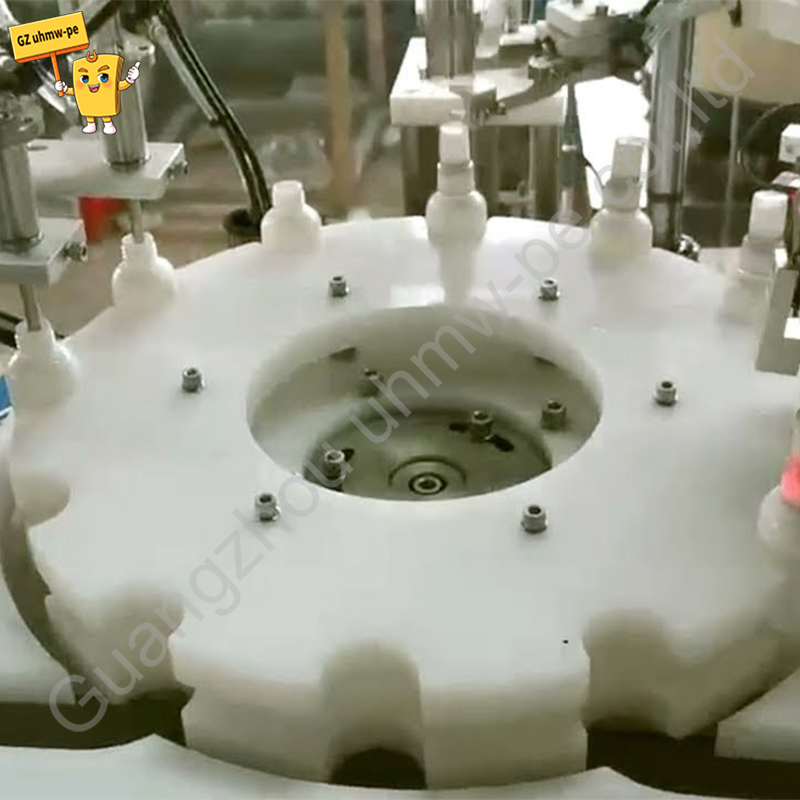

Though small, paddles play a critical role in bottle separation, positioning, and transition. Traditional metal or nylon paddles, constrained by material limitations, have become an invisible ceiling on production line efficiency:

Metal Paddles: Wear-resistant but prone to product scratching, generate high noise, require lubrication, and pose contamination risks.

Standard engineering plastics: Gentle on products but exhibit short wear life, frequent replacements, and high overall costs.

Guangzhou uhmw-pe Co., Ltd.'s precision-machined ultra-high molecular weight polyethylene (UHMW-PE) pusher wheels were engineered to shatter this ceiling. They represent not merely a replacement part, but a future-oriented upgrade to production line efficiency.

II. Core Technical Advantages: How UHMW-PE Creates Tangible Value for You

Our pulleys transform UHMW-PE's exceptional properties into tangible operational advantages:

1. Value Proposition: Reduce Costs, Boost Efficiency, Directly Increase Profit Margins

Unmatched Wear Resistance: Outlasts nylon by several times, enabling extended continuous operation. This translates to reduced spare parts inventory, lower replacement frequency, and decreased labor costs—freeing resources for core production.

2. Value Proposition: Safeguard Quality, Protect Brand Reputation

Superior Impact Resistance & Self-Lubrication: Gently contacts product surfaces, effectively eliminating scratches, indentations, and abrasions to ensure every item reaches the market with flawless appearance. Its self-lubricating properties eliminate the need for lubricants, removing potential contamination sources for food and pharmaceuticals while ensuring safety and compliance.

3. Value Proposition: Silent & Stable Operation, Optimized Production Environment

Ultra-low friction coefficient and shock absorption: Equipment operates smoother and quieter. This not only reduces workshop noise pollution and improves the working environment but also minimizes collateral damage to other equipment components caused by vibration.

III. Successful Application Scenarios: Industries We Serve and Our Solutions

We deeply understand the production characteristics of various industries, and our customized pulleys have become the secret weapon for many leading enterprises:

Scenario 1: High-Speed Beverage Filling Line

Challenge: High-speed friction between PET bottles and pulleys generates debris and noise.

Our Solution: Ultra-high wear resistance and low friction coefficient ensure smooth operation at high speeds, protecting bottle gloss without abrasion.

Scenario 2: Craft Beer and Glass Bottle Filling Line

Challenge: Glass bottles are prone to collisions, posing risks of breakage and high loss rates.

Our Solution: Superior impact resistance effectively cushions collisions, significantly reducing breakage rates and downtime for cleanup.

Scenario 3: High-Viscosity Product Filling Line (e.g., jam, honey, detergent)

Challenge: Material adhesion causes wheel blockages and malfunctions, requiring frequent cleaning.

Our Solution: The non-stick properties of UHMW-PE simplify and expedite cleaning, ensuring continuous and stable production line operation.

IV. Why Choose Us? — Full Process Control from Materials to Finished Products

We are not just a manufacturer; we are your trusted technical partner.

Materials Science Experts: We exclusively use premium UHMW-PE raw materials to guarantee exceptional and consistent intrinsic performance.

Precision Manufacturing Partner: Equipped with advanced CNC machining centers and specialized processes, we accurately transform your drawings or samples into reliable, durable components with strict tolerance control for seamless installation.

Customized Services: Regardless of your production line's origin or equipment model's uniqueness, we provide one-on-one customized development services.